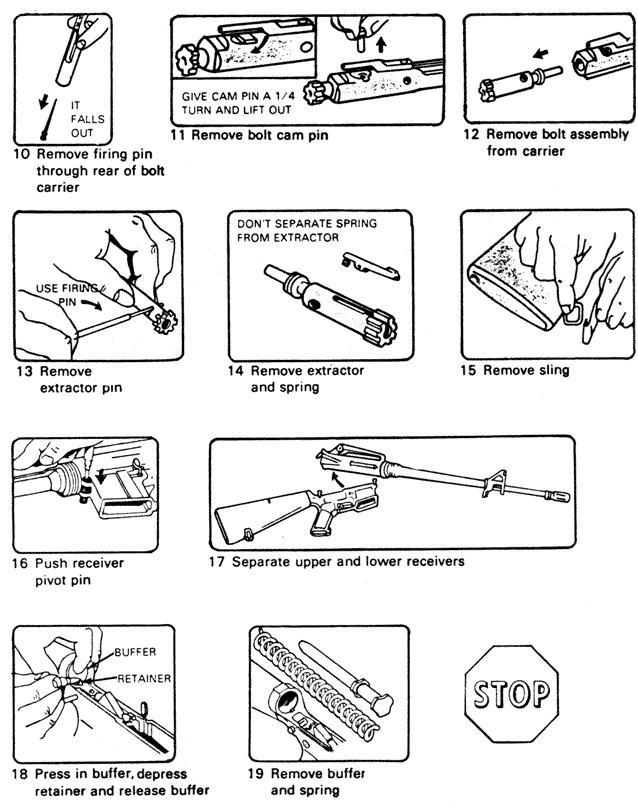

M16A1 Disassembly/assembly instructions

Soldier's Manual for Skill Level 1, unknown date (probably post 1975)

M16A1 Disassembly:

Soldier's Manual for Skill Level 1, unknown date (probably post 1975)

M16A1 Disassembly:

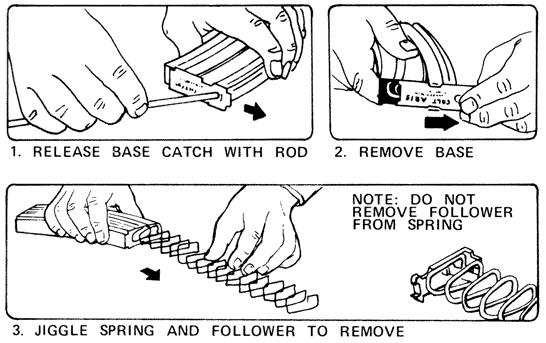

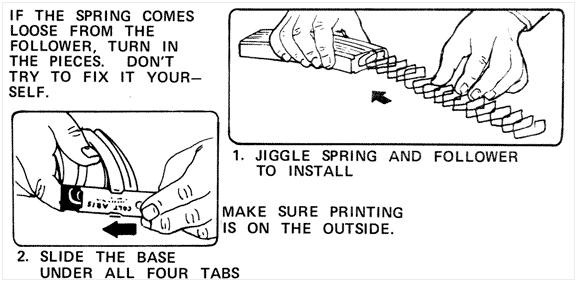

Magazine Assembly

Care and Cleaning.

Cleaning Rifle. Clean and lightly lubricate with LSA the lugs in barrel extension, bore. and chamber. Clean and lightly lubricate the bolt carrier. Lubricate slide cam pin area, piston rings, outside bolt body, and in bolt carrier key.

(CAUTION: Apply only a light coat of LSA to firing pin and firing pin recess).

Use rifle bore cleaning compound (RBC) to clean powder fouling in the upper receiver. Clean outside surface of protruding gas tube with a worn bore brush. Coat all other surfaces with lubricant. Apply a light coat of LSA to buffer, action spring, and inner surfaces of lower receiver extension. Use generous amount inside lower receiver and on all components.

Cleaning Magazine. Wipe dirt from tube, spring, and follower, then lightly lubricate the spring.

Cleaning Ammunition. Use a clean, dry cloth to wipe dirt and foreign matter from ammunition. Do not coat with oil.

Cleaning Rifle. Clean and lightly lubricate with LSA the lugs in barrel extension, bore. and chamber. Clean and lightly lubricate the bolt carrier. Lubricate slide cam pin area, piston rings, outside bolt body, and in bolt carrier key.

(CAUTION: Apply only a light coat of LSA to firing pin and firing pin recess).

Use rifle bore cleaning compound (RBC) to clean powder fouling in the upper receiver. Clean outside surface of protruding gas tube with a worn bore brush. Coat all other surfaces with lubricant. Apply a light coat of LSA to buffer, action spring, and inner surfaces of lower receiver extension. Use generous amount inside lower receiver and on all components.

Cleaning Magazine. Wipe dirt from tube, spring, and follower, then lightly lubricate the spring.

Cleaning Ammunition. Use a clean, dry cloth to wipe dirt and foreign matter from ammunition. Do not coat with oil.

The history of the M16 did not start off well when it was first deployed and issued to ground troops in the Vietnam War. For all the testing that was performed on this weapon, as it turns out, it was not the fault of the designer, Colt Firearms, nor was it a bad rifle, but the blame for it's poor performance was the U.S. Army itself. The earliest versions of this rifle were identifiable by the 3 prong muzzle flash suppressor at the end of the barrel. The newer models had a fully enclosed suppressor. Click on the link below to read a brief story copied from a monthly magazine article from the VFW - Donated by Tony Adams, rifleman, B 2/12th, 1968